GSF Galaxy ll Jack-Up Rig

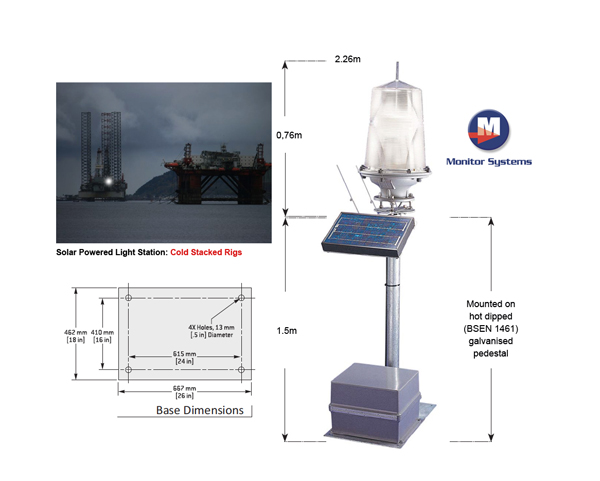

Solar Powered Light Station for GSF Galaxy III and GSF Monarch

RPD M1000 Rack Phase Differential Monitoring and System Commissioning