Sedco 711 Semi-Submersible Rig

(AIS) Automatic Identification System: System solutions for monitoring and marking cold stacked rigs

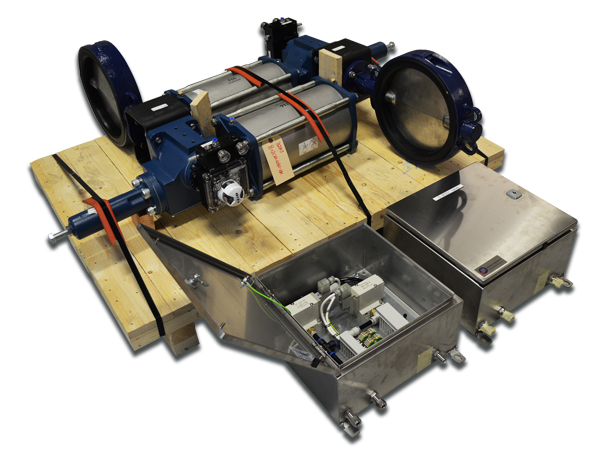

(BOD) Ballast Overboard Discharge Valves (ABS Approved)

Reverse Osmosis Watermaker Supply and Installation