Drilling DAQ for New Client

Advanced Drilling DAQ System Delivered for Tender Assist Rig Operation.

Monitor Systems has recently delivered an integrated Drilling Data Acquisition (DAQ) system to support operations on a Tender Assist Vessel and its associated Drilling Package.

Based on Monitor Systems standard DAQ platform with enhancements to optimise it for the Tender Vessel/ Drilling Package configuration the system provides clear, real-time insights into drilling activity, enhancing operational awareness and enabling informed decision-making throughout the drilling process.

Built around proven Siemens automation technology with a fibre optic communication backbone, the system brings together performance, reliability, and usability in a package built to meet the vessel specific requirements.

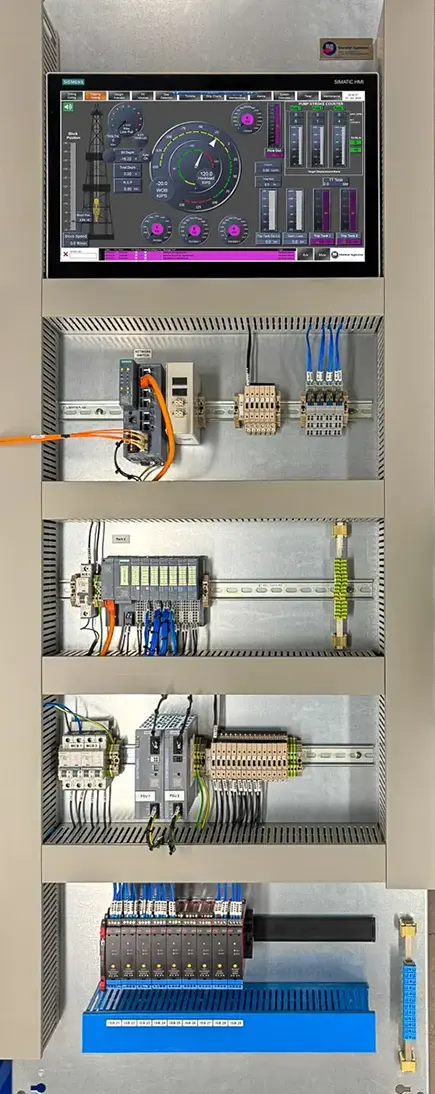

Process Enclosure - Installed on the Tender Vessel

The core of the DAQ system is located on the Tender Vessel. This enclosure interfaces with a wide range of field instrumentation and processes vital data.

A Siemens HMI is mounted on the front of the enclosure, providing vessel-based operators with a clear, responsive display of key data. The internal architecture includes Siemens PLC, I/O hardware, and a fibre network switch, designed for continuous performance in a demanding offshore environments.

A separate barrier enclosure was provided for interfacing with equipment and signals located in hazardous areas.

Rig-Side DAQ Enclosure

A second enclosure was installed on the Drilling Package. This enclosure is designed for signal handling and data collection from various rig-based instrumentation, including torque and RPM, standpipe & mud flow sensors, third party systems such as top-drive interface, and other analogue and digital inputs.

Intrinsically safe barriers are incorporated for connection of zone-rated field devices, reusing existing equipment where possible.

Central SCADA Server

The system is integrated with a powerful Siemens SCADA server housed in a compact 19” rack cabinet. This server manages data from both the rig and the tender vessel, offering full system visualisation, data logging, alarm handling, and trend reporting via WinCC SCADA software.

Operator Stations

To give key personnel full access to drilling data, the system includes a range of operator workstations. These were supplied to the Driller, Toolpusher, OIM, Mud Logger, and Company Man.

The Driller's station features a robust 22” touchscreen panel PC, suitable for use in Zone 2 hazardous areas. Other locations, including the Toolpusher's office and Tender Vessel offices, are fitted with tower PCs, full-sized monitors, and standard keyboard/ mouse input devices.

Each workstation is connected to the drilling network and preloaded with SCADA client software, ensuring consistent access to live and historical data.

Integrated Gas Detection

In addition to drilling data, the DAQ system monitors the presence of hazardous gases. Six hydrogen sulphide (H₂S) and six combustible gas sensors were integrated into the system.

Final Commissioning and Handover

Following delivery, Monitor Systems Engineering completed on-site commissioning of the full DAQ system. This included final configuration, testing, and signal verification — ensuring the system was fully operational and ready for use by the offshore team.

This delivery reflects Monitor's ongoing commitment to providing tailored, high-performance monitoring solutions to the offshore energy sector.